(PRESS RELEASE) NEW YORK — What’s in your platinum? Sounds like an easy enough question, yet many retailers and industry members do not know the answer. To assist in finding the answer to this question, Platinum Guild International USA is launching a new initiative to educate the industry on the importance of understanding different platinum alloys and how they impact jewelry manufacturing.

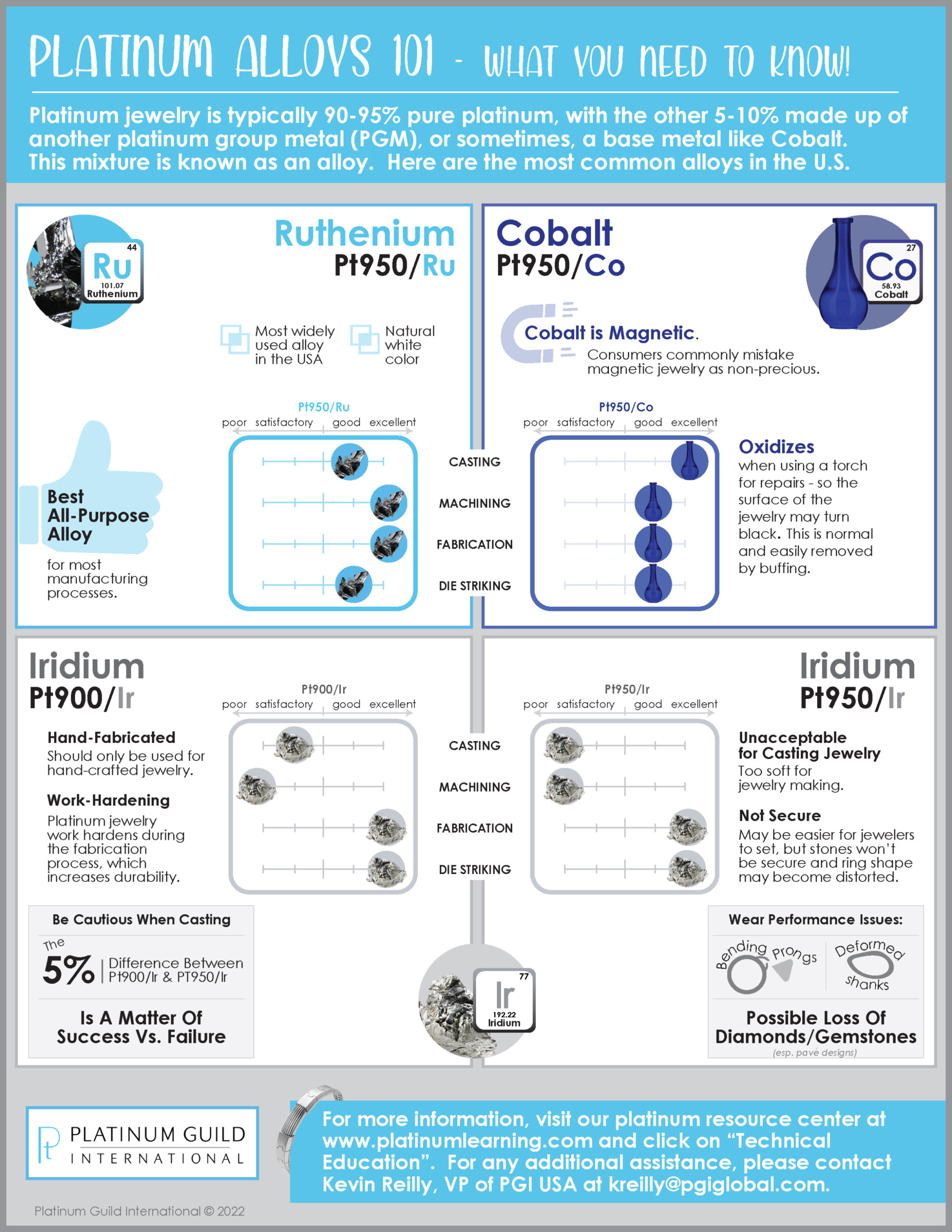

Nearly all precious metal jewelry is made from alloys, a mixture of the primary precious metal and one or more other precious or base metals. While many may be aware that platinum is naturally white, ensuring it will not fade or change color over time; durable, meaning a customer will not lose metal as a result of normal wear and tear unlike other metals; and that it holds diamonds and gemstones most securely, retailers may not know the alloy composition of the platinum jewelry they currently sell. Other metals used in creating platinum jewelry alloys commonly include Ruthenium, Cobalt, and Iridium, in various percentages.

These percentages are of utmost importance, as the alloy composition can significantly impact wear performance. Below is an easy-to-reference infographic summarizing the most commonly used platinum jewelry alloys in the US and their impact on jewelry manufacturing.

The PGI USA Platinum Alloys 101 infographic is available for download here via PlatinumLearning.com.

Most platinum jewelry in the US is made from alloys that are best for all manufacturing processes like casting, machining, die-striking and/or hand-fabricated designs. As the infographic shows, PGI USA has identified one alloy that should not be considered for casting jewelry or setting gemstones, as the resulting product may not meet long-term quality control standards. Posing the question ‘What’s in Your Platinum’ to manufacturers and retailers will help PGI USA to share important guidance to those companies using a problematic alloy. The goal is helping them switch to a better alternative that ensures optimal gemstone security, wear performance and customer satisfaction.

Advertisement

Teresa Frye, President of Techform Advanced Casting Technology, commented “All alloys are not created equal, so it’s important to know what alloy is being used in your jewelry.” She continued, “Most platinum jewelry in the US is 95% platinum – but that other 5% will determine the difference between optimal performance, or something that’s too soft for jewelry making.”

“Platinum is an important part of our business and I’ve always made the assumption that all platinum alloys are essentially created equal – when in actuality there’s some major differences,” explained Alexis Padis, President of Padis Jewelry. “After speaking with the team from PGI, I was then able to have a more informed discussion with my caster to ensure we are producing the best platinum product available for our customers.”

Kevin Reilly, PGI USA’s Senior Vice President, shared “After having the alloy conversation with several key retailers and manufacturers in the past few weeks, we are encouraged by the responses and the eagerness to learn. Companies are already taking active steps to ensure the platinum product they are producing and selling will yield a lifetime of customer satisfaction.”

PGI USA has set up a dedicated web page, here, for retailers and manufacturers to provide information on the specific alloys being used in their platinum jewelry.

Those interested in learning more about what’s in their platinum should contact Kevin Reilly, PGI USA’s SVP at kreilly@pgiglobal.com.